Stone Crusher Spillage

Safe operation and use of mobile jaw crushers HSE

Mobile crushers are used in a wide range of industries, including quarrying, ore processing and recycling of demolition waste This guidance is for all those with responsibilities for the 展开2020年6月5日 In the business of crushing materials like aggregate and demolition waste, maintaining the flow of this loose material through a crushing and conveying system is an important responsibility Proper care must be Minimizing Spillage While Crushing and Conveying Being on the access platform during normal operation presents the following risks: Struck by objects ejected from the crusher, such as pieces of stone or metal Being pulled into the SAFE USE OF MOBILE CRUSHERS SCREENING PLANT NFDCDust emissions from the mobile stone crushing plant will arise mainly at: (a) the discharge point, (b) during the crushing process and (c) at the mouth of the conveyor belt In order to suppress CHAPTER 6 MITIGATION OF PREDICTED IMPACTS 61 Introduction Abstract: Crusher is a equipment that functions to break natural rock into smaller sizes according to the required specifications The crusher at the Lhoknga plant has a BDP (Best OPTIMALISASI SPROCKET APRON FEEDER UNTUK MENGURANGI 2021年2月1日 Spillage or overflow occurs primarily when loading at one of the three, main material transfer stations:1 Undercrusher conveyor – spillage, so clean/keep clear, Best Practices: Crusher Housekeeping for Peak Production

.jpg)

How to avoid material spillage on a belt conveyor in a stone

To avoid material spillage on a belt conveyor in a stone crushing line, several measures can be implemented Here are some effective strategies:1 **Proper LSpillage can also occur around scrubbers, crushers, shaker decks, classifier stations, and final rinse screening stations Spillage in these areas can be caused by worn chutes, excessively SAND, GRAVEL, AND CRUSHED STONE ONTHEJOB TRAINING Repair fuel leaks immediately, clean up residual fluid, lubricant or spillage at once Safe Work Procedure: If an emergency situation occurs while conducting this task, or there is an Crusher General Safety Construction SafetyThis document provides an environmental guideline for setting up temporary stone crushing plants for construction projects by public departments in Mauritius It outlines the key environmental issues to consider, including site selection, 30stone Crushing Plant PDF PDF Environmental DRAGON 10 – Mobile Closed Circuit Crusher and Screening Plant – New Technology Limestone , River Stone , Mining Crusher DRAGON 10 – Closed circuit crushing system is all collected in one single platform and can be DRAGON 0628 2:35 PM SP1202 Page 5 of 10 Crusher Lock Out 1 Install one or more locks to hold the master switch lever in the OFF position 2 Turn the master key to the OFF position and remove the key 3 Disconnect the batteries 4 Place one or moreSAFE WORK PROCEDURE FOR Crushing Operations Screener

.jpg)

SAFE USE OF MOBILE CRUSHERS SCREENING PLANT NFDC

15 Blocked Crushers Causes of crusher blockages can be grouped under two main headings: Stalling due to: Electrical or mechanical failure Material jammed in the chamber causing an overload Overfeeding material Entry of tramp metal or wood Excessive2021年7月28日 ABSTRAK PT Semen Baturaja Tbk (Persero) merupakan salah satu pabrik yang menghasilkan semen sebagai bahan baku pembangunan atau konstruksi dari skala kecil sampai proyek yang skala besar, yang (PDF) Pemeliharaan Mesin Limestone Crusher Di PT Semen 2023年6月2日 Efficient material handling is vital for smooth productive crushing and screening operations Here are some key considerations for achieving optimal material handling: – Proper loading and feeding techniques: Implement proper loading and feeding techniques to ensure a continuous and consistent flow of material Crushing and Screening Best Practices: Maximizing Efficiency and spillage control in mining industry trends BWZ Heavy Duty Apron Feeder BWZ series heavy duty apron feeder designed by SKT is one new type highefficiency Get Price >> Iron Ore Department of Industry, Tourism and Resourcesspillage control in mining industry trends2008年8月27日 Since no final products are produced in the secondary crushing stage, the crusher’s only task is to provide a good feed to the tertiary crushers The setting of the secondary crusher is, therefore, adjusted so that the tertiary crusher can operate with a feed that offers the best tradeoff between cost and ability to generate correctly shaped final productsCrushing Plant Performance Optimization AggNetRisk assessment Rock crusher Free download as Word Doc (doc / docx), PDF File (pdf), Text File (txt) or read online for free Safe operation and use of mobile jaw crushers Scope of this guidance Mobile crushers are used in a wide range of industries, including quarrying, ore processing and recycling of demolition waste Risk Assessment Rock Crusher PDF Industries Waste

Crusher Clicker ️ Play on CrazyGames

2025年1月3日 Crusher Clicker is an addictive game where you smash rocks and crystals, then upgrade to enhance your crushing power and speed It#39;s like operating a hydraulic press but with a satisfying, stressrelieving twist Boost your crusher#39;s power, speed, and gravity for even more dramatic destruction Get lost in the colorful physics and the endlessly engaging Fig 1 Typical mobile stone crusher Feeding If the mobile crusher is to be fed directly by a loading shovel or excavator, then: Slips and Trips spillage Keeping clear working areas clear of spillages improves operational efficiency and also reduces the risk of Safe operation and use of mobile jaw crushers HSEIn a conetype crusher the work done on the stone is performed by the mantle and concave (Fig 1) The amount of reduction that can be achieved is controlled by two major mechanical factors within the crushing chamber: first, the conical angle, shape, and Scientific Methods to Design Crushing and Screening Plants(look for spillage, dust) Work Health and Safety Resource Manual Page 17 of 20 Mobile Crushing Plant Inspection Checklist Inspection item: Y N N/A Risk Level Details of nonconformance Photo (if required) Are the grease points easily Mobile Crushing Plant Inspection Checklist studylibOptions: spillage conveyor, lump breaker Crusher feeding Intake of runofmine material directly from dump trucks Unloading of multiple trucks at once Material size up to 1,500 mm Each unit is tailormade to suit the crusher Wagon Apron Feeders AUMUND GroupYou've already forked sbmsbm/sbm stone crusher spillagemd at master sbm

Practical considerations on improved feeding arrangements for cone crushers

Cone Crusher Function zA cone crusher has an annular crushing chamber zThe CSS runs around the chamber so the action is basically rotational zRaw material enters the chamber on the OSS and is crushed one hlf lti lt bthCSShalf revolution later by the CSS zThis cyyp pcle takes place in most cone crushers 5 to 6 times per tender for providing fixing mobile crusher single conveyor all purpose stone concreet crushing plant, crusher size 16x9, conveyor size 25x18 Due Date : Jan 6 , 2025 Tender Value : 1985 LakhsCrushing tenders in Chhattisgarhcrushed stone industry in conducting effective onthejob training (OJT) of new employees, or empl oy ees r eassi gned to di fferent j obs The use of tr ai ni ng mater ial s, such as thi s module, is an important part of an effective, systematic, OJT program SAND, GRAVEL, AND CRUSHED STONE ONTHEJOB TRAINING Nesans Crusher Plant Belt Conveyor Systems come with Supreme quality combined with reliable engineering With More than 500 Km of total conveyor installations around India, we are a power player in the market of industrial conveyorsCrusher Plant Belt Conveyor Systems Manufacturer from Upon inspection he found that one of the major issues was on the B06 conveyor, which transported crushed limestone from the storage dome to both kilns through an underground tunnel Akula determined that the main transfer point for B06 was not able to sustain the force, weight and volume being fed to it, leading to a number of belt and component problems and Conveyor Drop Points – Preventing Damage and Spillage2024年5月25日 Choose right conveyor belt for stone crusher 1Primary Crushing Stage; 2Secondary Crushing Stage;3Tertiary Crushing and Final Processing : [ protected] Phone:+86 HomeSelecting Conveyor Belt for Stone Crusher Systems

.jpg)

Safe Operation and Use of Mobile Jaw Crushers

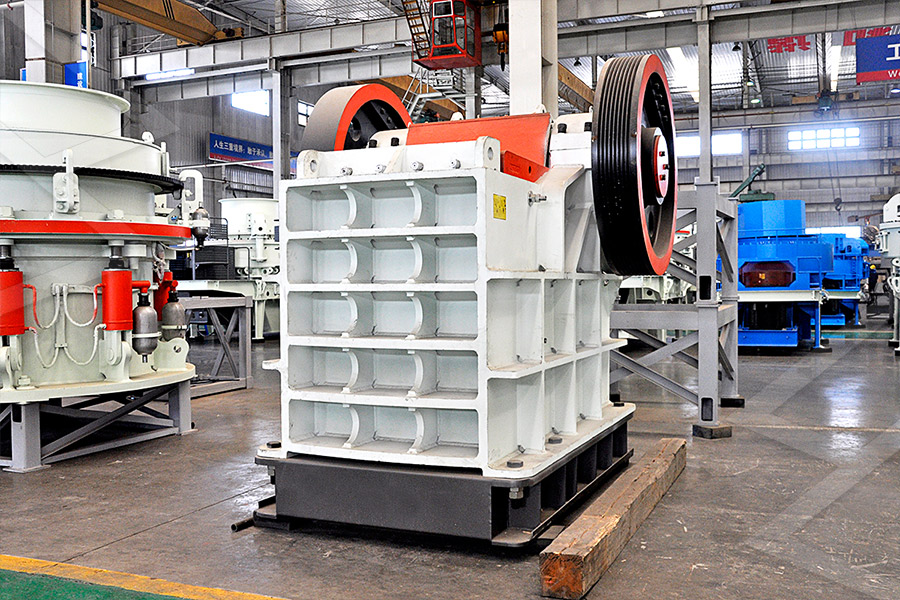

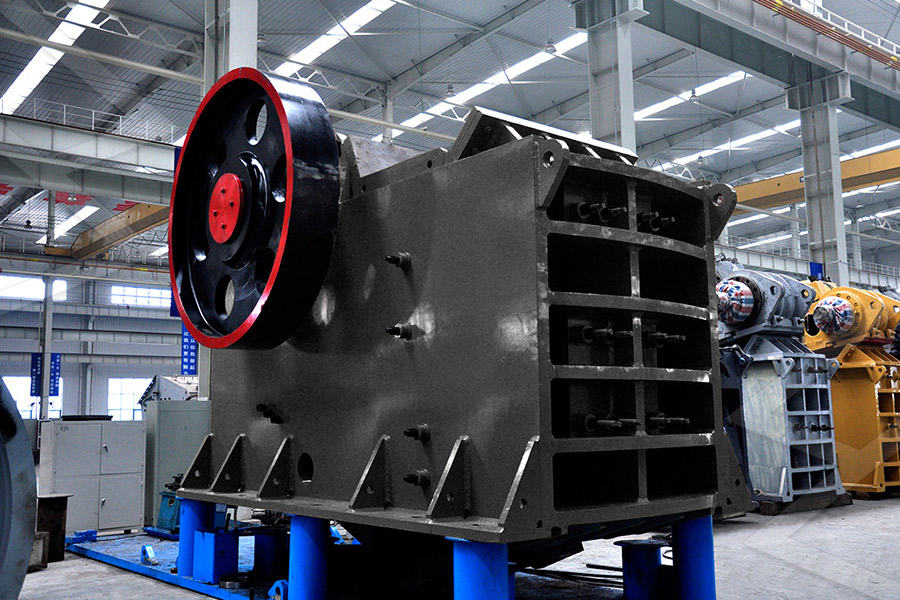

This document provides guidance on safely operating mobile jaw crushers It outlines key risks like machinery guarding and clearing blocked crushers When a crusher becomes blocked, the feed should be stopped and excess material 2023年2月28日 Rock crushing comes with its own set of risks attached to it Working in the vicinity of crushing equipment and aggregates can give rise to a lot of potential danger One needs to be wellaware of all the ways they could How to Minimize Rock Crusher Injuries? – Promaninfi2024年10月18日 Stone Crushers The stone crushers are the primary machines in the processing line, responsible for crushing large rocks into smaller, manageable sizesThis initial size reduction is critical for subsequent processing steps Collaboration with Belt Conveyors Once The Role of Belt Conveyors in Sand Gravel Making PlantStone Crusher XHP Series Multi Cylinder Hydraulic Cone Crusher Get the Price Now View details About Us Xingaonai Heavy Industry Group Co, Ltd Xingaonai Group specializes in the RD and manufacture of crushing, grinding, screening, feeding, conveying Cone CrusherJaw CrusherStone CrusherXingaonai Heavy Crushing Plant Process Optimisation Design of processes in order to find the most efficient solution to a specific task is a difficult problem Often the number of solutions are large and the optimal solution is therefore difficult to identifyx000D Crushing plant process design is no exception from this statement In order to find the best solution issues like equipment selection Crushing Plant Process Optimisation AusIMMSTONE CRUSHER Stone Crusher (also known as Rock Crusher) is a mechanical comminution device engineered to fragment large blocks of natural rock (eg, granite, basalt), metallic ores (eg, iron ore, copper ore), or recycled aggregates (eg, construction debris, concrete rubble) into smaller, controlled particle sizesStone Crusher: Efficient Rock Crushing Solutions

.jpg)

Dust Control Handbook for Industrial Minerals Mining and

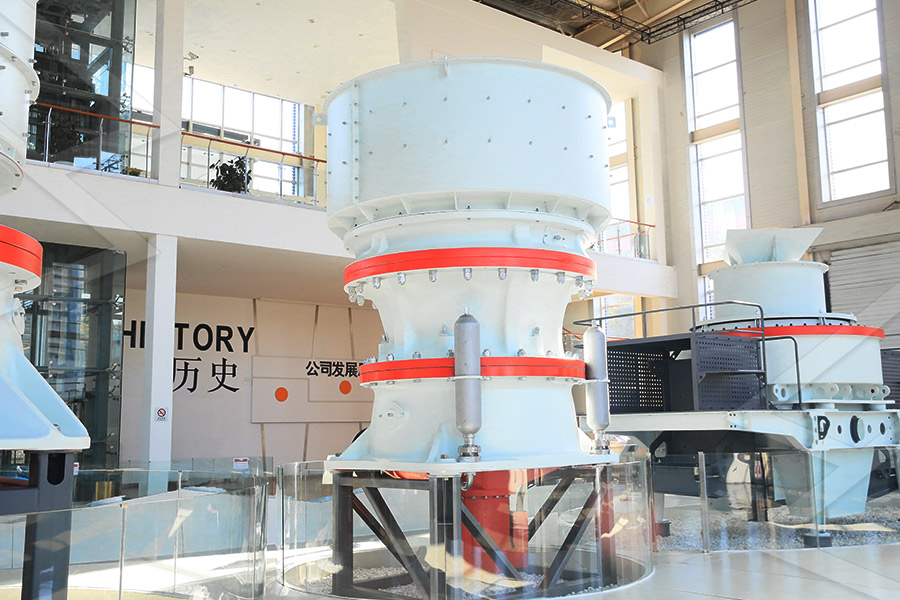

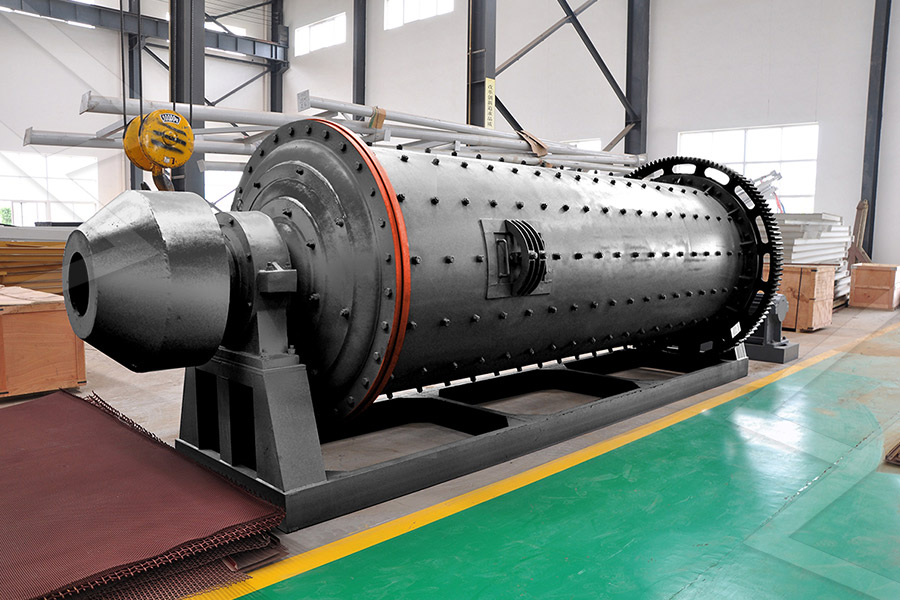

Dust Control Handbook for Industrial Minerals Mining and Processing Andrew B Cecala, Andrew D O’Brien, Joseph Schall, Jay F Colinet, William R Fox,DEPARTMENT OF HEALTH AND HUMAN SERVICES Centers for D isease Control and Prevention3 Crusher Beberapa macam peralatan pemecah batu (stone crusher) meliputi : a Jaw Crusher b Gyratory Crusher c Impat Crusher d Hammer Crusher (Limestone Crusher dan Siltstone Crusher) e Roller Crusher (Shalestone Crusher) 4Laporan MBKM Abulyatama Spillage Skripsi PDF ScribdOur crushers have been designed to fulfil the various requirements of stone quarries, mining facilities and industrial facilities We offer a variety of sizes and styles in three different crushing groups—primary, secondary and tertiary—which are used to crushCRUSHING SCREENINGFrom construction to landscaping, we offer highquality stone products for any project Our inventory includes Crusher Run, Block Material, Shot Rock, Rip Rap, and graded stones in various sizes We have grown to supply the local community with thousands of H H Rock Inc Rock LimestoneDRAGON 10 – Mobile Closed Circuit Crusher and Screening Plant – New Technology Limestone , River Stone , Mining Crusher DRAGON 10 – Closed circuit crushing system is all collected in one single platform and can be DRAGON 0628 2:35 PM SP1202 Page 5 of 10 Crusher Lock Out 1 Install one or more locks to hold the master switch lever in the OFF position 2 Turn the master key to the OFF position and remove the key 3 Disconnect the batteries 4 Place one or moreSAFE WORK PROCEDURE FOR Crushing Operations Screener

.jpg)

SAFE USE OF MOBILE CRUSHERS SCREENING PLANT NFDC

15 Blocked Crushers Causes of crusher blockages can be grouped under two main headings: Stalling due to: Electrical or mechanical failure Material jammed in the chamber causing an overload Overfeeding material Entry of tramp metal or wood Excessive2021年7月28日 ABSTRAK PT Semen Baturaja Tbk (Persero) merupakan salah satu pabrik yang menghasilkan semen sebagai bahan baku pembangunan atau konstruksi dari skala kecil sampai proyek yang skala besar, yang (PDF) Pemeliharaan Mesin Limestone Crusher Di PT Semen 2023年6月2日 Efficient material handling is vital for smooth productive crushing and screening operations Here are some key considerations for achieving optimal material handling: – Proper loading and feeding techniques: Implement proper loading and feeding techniques to ensure a continuous and consistent flow of material Crushing and Screening Best Practices: Maximizing Efficiency and spillage control in mining industry trends BWZ Heavy Duty Apron Feeder BWZ series heavy duty apron feeder designed by SKT is one new type highefficiency Get Price >> Iron Ore Department of Industry, Tourism and Resourcesspillage control in mining industry trends2008年8月27日 Since no final products are produced in the secondary crushing stage, the crusher’s only task is to provide a good feed to the tertiary crushers The setting of the secondary crusher is, therefore, adjusted so that the tertiary crusher can operate with a feed that offers the best tradeoff between cost and ability to generate correctly shaped final productsCrushing Plant Performance Optimization AggNetRisk assessment Rock crusher Free download as Word Doc (doc / docx), PDF File (pdf), Text File (txt) or read online for free Safe operation and use of mobile jaw crushers Scope of this guidance Mobile crushers are used in a wide range of industries, including quarrying, ore processing and recycling of demolition waste Risk Assessment Rock Crusher PDF Industries Waste

Crusher Clicker ️ Play on CrazyGames

2025年1月3日 Crusher Clicker is an addictive game where you smash rocks and crystals, then upgrade to enhance your crushing power and speed It#39;s like operating a hydraulic press but with a satisfying, stressrelieving twist Boost your crusher#39;s power, speed, and gravity for even more dramatic destruction Get lost in the colorful physics and the endlessly engaging Fig 1 Typical mobile stone crusher Feeding If the mobile crusher is to be fed directly by a loading shovel or excavator, then: Slips and Trips spillage Keeping clear working areas clear of spillages improves operational efficiency and also reduces the risk of Safe operation and use of mobile jaw crushers HSE